17

17

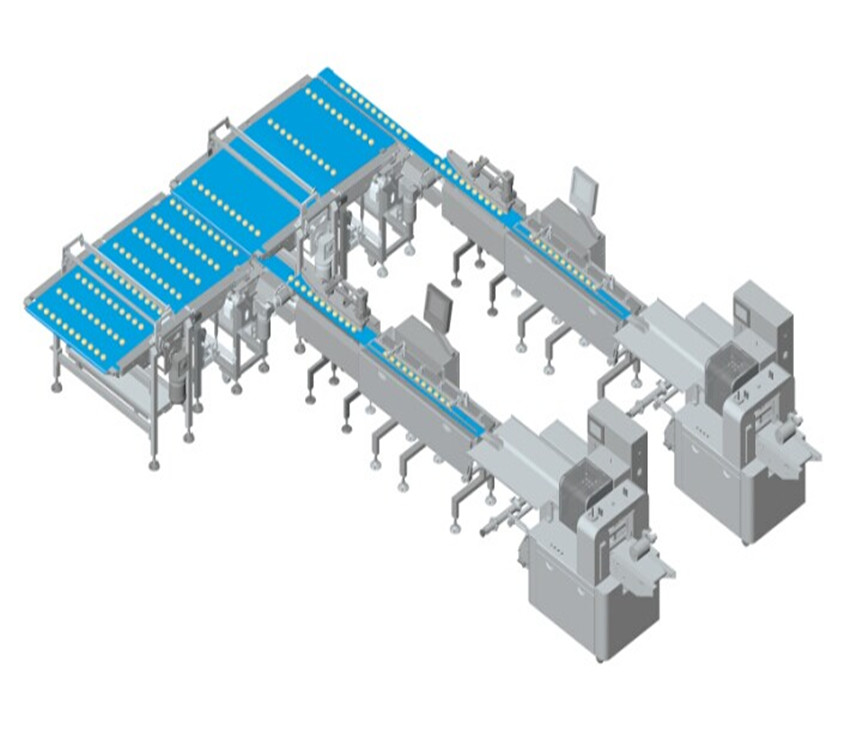

一拖一全自动理料线,配备350DS包装机

1、定位送料机构

LEIZU传感器、PU皮带。配有软性刮板、共三组0.4KW施耐德变频器、7寸威伦触摸屏、海德利控制器,无工具拆卸皮带机构。

2、拉开皮带

PU皮带,无级调速机构。

3、送料机构与350DS包装机配套优点:

包装速度可达330包/分钟(视物料而定),下料机构可自动补料,中途*人工放料,可节省人工操作成本。缺料*手动停机,350DS可感应料位缺料,走膜和切刀停止工作,等待链条自动补料后运行,不浪费薄膜,节省耗材成本。

包装和交货

包装:木箱

交货期:待定

Features

Clear-up,feeding and packing automatically without man-power operation.

Clear-up machine and positioning feeding machine can be operated separately.They can work in synchroization with producing line,synchronous change speed,automatic stop/startup in case of material absence/supply and so on.

It can match headly HDL series and DF series packing machine

Tominimize secondary pollu tion of products due to traditional manpower arrangement.

Clear-up correctly and the speed is up to 300bags/min with high effciency.

Simple frame,easy maintenance,all conveyor belts can be detached quickly without using any tool,ensuring food safe and healthy.

Packaging & Delivery

Packaging Details: Inner plastic package and outer is wooden cases,standard export package

Delivery Detail: TBD

Specifications

HDL-200 Single feed packing line

PLC controlled.

CE standard certificate.

Design for capacity

Clear-up arranging form: It clears-up the product first and then arrange to one line by the fold line motion of several belts. This form is suitable for product which has small length and width, round product, product in a mess line or in irregular.

Basic configuration :

SICK sensor, PU belt and with soft paddle, Panasonic frequency control of motor speed, belt mechanism without any tear tool.

Form: The product will be sent into packing system after the precise positioning, achieving the automatic connection with packing system.

According to product’s nature and packing speed, it has different structure and belt’s several different positioning system.

Basic configuration :

Panasonic frequency control, Panasonic servo motor, Dachuan control unit, touch screen, belt mechanism without tear tool. The product will be sent into packing system after the precise positioning, achieving the automatic connection with packing system.

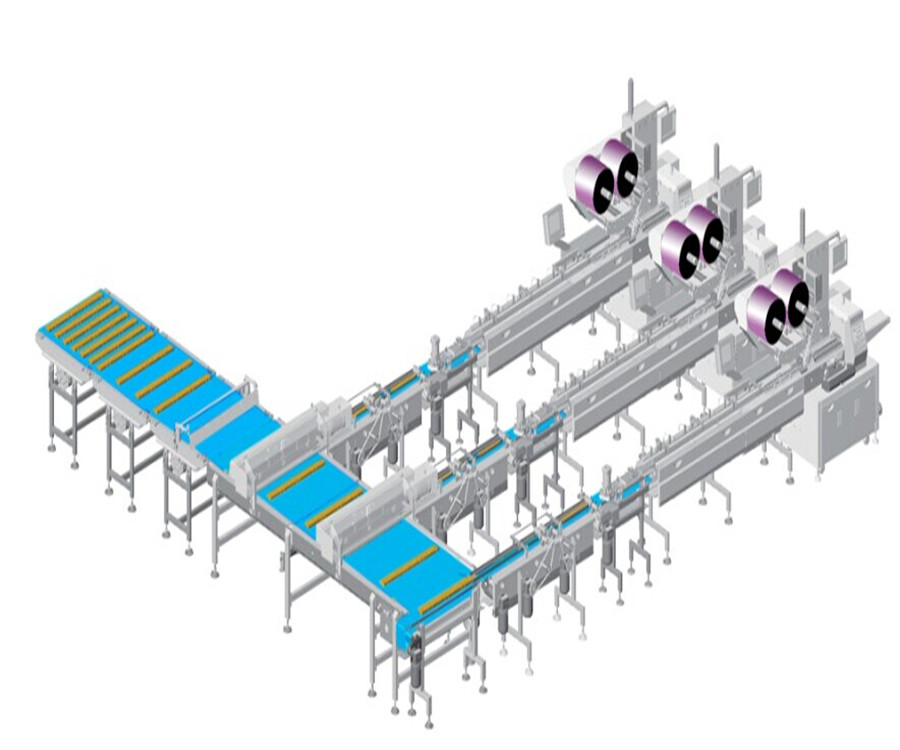

Headly automatic clear-up packing line, which absorbs in excellent technology from Italy, Swiss and combines the need and development trends in domestic, designing the equipment in high-tech and elaboration, making the Headly automatic clear-up packing line stand on the lead edge of high-end.

Headly automatic packing line can be connected with the production line in perfect status, which can be automatic lined, distributed, turned, cleared, position feed, packed, without any person control, achieving the automatic packing, with high efficiency and without pollution.

According to the products' nature and output, it can be allocated by single packing and multi-station packing. The speed of single packing is based on products' nature and positioning system structure, it can be packed by 150bags/min to 400bags/min.

主要性能和结构特点:

1、自动装托理料线由拉距输送机,分配输送机,自动理料机组组成,分托机构、入托机构及自动包装机组成,对月饼等产品进行拉距整理,定位,分托,入托,包装。达到生产连续、有序、废品率低、包装效果好的效果,同时可放脱氧剂或酒精片。

2、单条线包装速度可达120包/分钟。

3、整线采用220V 50HZ电源,单条理料线(含包装机)功率为3.2KW,输送机共功率为0.8KW,用电量低。

优势:

1自动装托理料线通过分托机构把托盒分开,两套系统整合一起实现自动进料、自动装托、自动包装的效果,实现自动化生产,提高食品安全性及效率,通过自动投包机同时可放脱氧剂或酒精片。

2控制系统采用PLC控制,触摸屏显示,良好的人机界面,操作直观、方便。

适用范围:

自动装托理料线主要针对月饼、肉松饼、蛋糕类等外形规则及需带托包装的产品,

技术参数:

|

枕式自动包装机型号(Type) |

HDL-250(可选) |

|

运行速度(Packing speed) |

40-230包/分钟bags/min |

|

封口形式(Bag forming type) |

三边背封Pillow type/fat pouch (3-side presealed) |

|

制袋尺寸(Bag size) |

长115-280mm,宽30-170mm,高5-65mm |

|

包装膜宽(Packing film width) |

Max.250mm |